Air Fluidization

Air Fluidization: efficient technology for conveying and mixing powders and bulk goods with air flow.

How does a process work by liquefying dry cement through air

The process of dry cement liquefaction with air refers to using air currents to transport, mix or improve the behaviour of dry cement powder or dry mixtures (such as mortar or dry concrete) during processing. This process is particularly relevant in industrial environments where bulk cement is processed.

How does this process work?

1. Air fluidization:

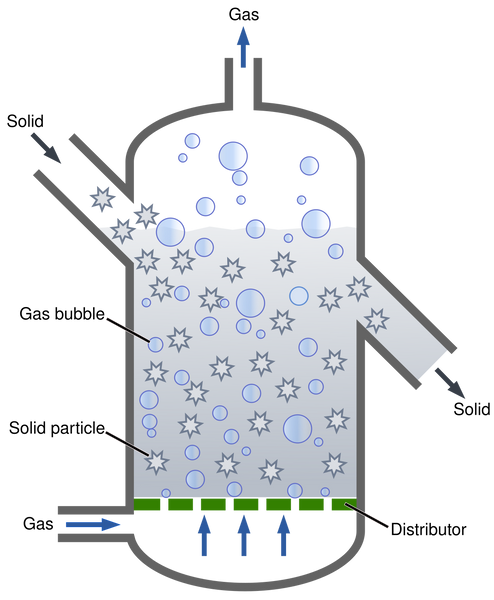

• Cement powder is placed in a special container or silo that is equipped with a perforated bottom or air inlet.

• Air is blown through the powder under pressure, bringing the particles into a near-liquid state. This process is called fluidization.

• The airflow reduces the friction between the particles, allowing the cement to flow freely as if it were a liquid.

2. Mechanism of air fluidization:

• The air flows create a pressure field that separates particles of the dry cement from each other.

• This ensures that the cement does not clump together and behaves as a flowing mass, despite remaining a powder.

3. Air transport:

• Once in this "liquid" state, the cement can be transported via air flows in pipes to storage locations, mixers or other processes.

• This is called pneumatic transport and is often used when filling silos or trucks.

4. Mixing or pouring applications:

• In specific applications (such as filling moulds or dry mortar), air can also be used to spread the cement powder in a controlled and even manner.

Applications

1. Industrial Processes:

• Cement plants use air fluidization to store and transport cement into silos.

• Pneumatic systems transport cement over long distances without mechanical conveyors.

2. Bulk Transport:

• Air is used to discharge bulk cement from trucks into silos to keep the cement flowing smoothly and prevent blockages.

3. Special Concrete or Mortar Mixers:

• Dry cement mixes are kept in motion by air currents to ensure a homogeneous mix before adding water.

Fluidizing Fabric / Air permeability 800 mmWG / Thickness 5 mm / Temperature up to 150 Degrees Temperature up to 150 Degrees

Fluidizing Fabric / Air permeability 800 mmWG / Thickness 5 mm / Temperature up to 150 Degrees

Benefits

• Efficient transport: Air-fluidized cement powder flows effortlessly through pipes or into silos.

• Reduced clogging: The process prevents cement from clumping or getting stuck in transport lines.

• Energy efficient: Pneumatic systems use relatively little energy to transport large quantities of cement.

• Dust reduction: Controlled handling of cement with air minimizes dust emissions.

Fluidizing Fabric / Air permeability 800 mmWG / Thickness 5 mm Temperature up to 250 Degrees

Fluidizing Fabric / Air permeability 800 mmWG / Thickness 5 mm / Temperature up to 250 Degrees

Key points to consider

• Air pressure control: Air pressure must be set accurately to ensure proper fluidization without spraying the cement.

• Homogeneity: Incorrect air distribution can lead to uneven particle distribution.

• Equipment wear: Cement powder can be abrasive and can damage pipes and fans if used for a long time.

Liquefying dry cement with air is, therefore, a clever technique that makes the transport and processing of cement more efficient and user-friendly.